See This Report about Waterproofing Auckland

The 15-Second Trick For Waterproofing Auckland

Table of ContentsThe Of Waterproofing AucklandThe 15-Second Trick For Waterproofing AucklandOur Waterproofing Auckland StatementsWaterproofing Auckland Fundamentals ExplainedWaterproofing Auckland Fundamentals Explained

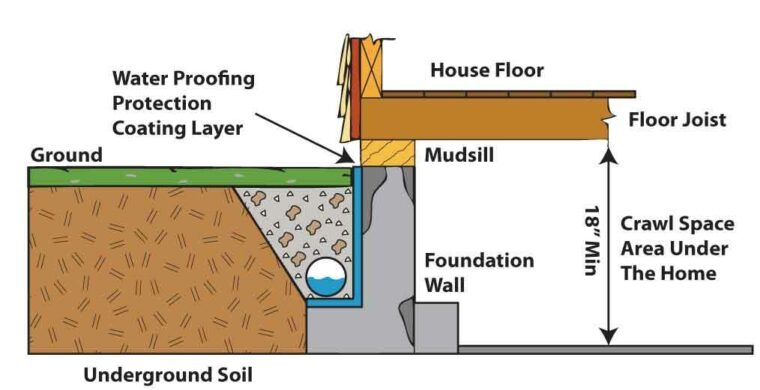

45m (18) in size, are stocked progressive slopes. The joints of these pipes are maintained open. The collecting chambers are created at ideal intervals and at transforming factors. The gathering chambers are not glued from the inside or outside, to get water from the surroundings. The perforated pipes are after that covered with loose products like chips as well as steel, to develop a filter media.The below ground water locates the means of least resistance with the filter media. The water is collected in the perforated pipes via the filter media.

The procedure for the below ground water tank is the exact same as that of the basement, with the exception of the following factors. A provision for a pump sump is made, rather than the gutter plan. The overflow pipeline lies at the preferred degree, to drain out the excess water. Inspect this pipeline for its tightness before the waterproofing job treatment.

The Only Guide for Waterproofing Auckland

If white or tinted joints are called for, then the grey cement joints are raked, and also white concrete or color cement slurry is used with a little travel over the surface for joints of a coordinating color. The surface is again cleansed with sawdust. to eliminate excess white or color concrete sticking to the polished china mosaic surface.

The base and accelerator are blended together in proportion by weight. This combined substance is then applied with a spatula or portable gun tools any place needed. Extra product is reduced off with a putty knife as well as a smooth vertical joint is created. Since the sealer is extremely expensive, use it.

For water-proofing of the horizontal expansion joint, setups ought to start from the R.C.C. stage of the building. Upside down beam of lights are taken to the place, for the expansion joint, side by side.

Socketing (stress grouting)' is a treatment to grout the concrete slurry by stress right into the porous concrete participant. For stopping unseen leakages in toilets, terraces, and also the basement, this method is generally used. Following a sequence of the work procedure. is observed. Initially, clean the surface where socketing is to be done.

Top Guidelines Of Waterproofing Auckland

Fix 25mm (1) G.I. outlet over the steel, using rich concrete mortar around the socket and also metal. If the waterproofing work treatment is not done correctly, it can posture issues. Fixings as well as maintenance of waterproofing can verify really bothersome for the customer.

is where the maximum water is made use of. Typically, the moms and dad piece of the W.C. unit has an I.W.C. Frying pan and also a concrete case of dimension 0. 9m x 1. 2m x 0. 6m. This instance is water-proofed after repairing the essential accessories such as P-trap, C.I. piece, W.C. frying pan, and so on unit can suggest the different factors of leakages, Click Here as listed here. The joint in between the C. 1/P. V.C. item as well as P catch. The joint in between the (tee) of external vertical stack as well as P.V.C./ C.I. item. The joint in between the P-trap and also I.W.C. pan. The joint between the flushing pipeline and I.W.C pan. All these joints need to be sealed with the appropriate sealer, at the corresponding stages during the implementation of the job.

Additionally, load all the gaps in the flooring of W.C. with cement. Check the joint between the P-trap and L.W.C. pan from above, by placing a hand into the trap. Seal this joint with M-seal, if it is partially open. Inspect the joint between the flushing pipeline and also L.W.C. frying pan by damaging only one tile, fitted specifically over the joint.

Waterproofing Auckland Fundamentals Explained

Open up the "Tee' of the vertical pile from the outside, with a ladder or zula and also observe the joint of C.I. piece and also Tee' with torchlight as well as seal it properly. If leak still persists, damage open the concealed flushing G.I. pipeline and inspect if it is watertight.

If this does not quit the leakage, break open the full system and also inspect the joint at the P-trap and also C.I./ P.V.C. pipe. Do the brand-new waterproofing work treatment totally with utmost treatment. Typically, 90% of leaks stop, if we accomplish the repair job as mentioned above, in the initial 4 points.

This can be checked by stopping the procedure of the clean hand basin as well as keeping these lines completely dry and operating them once again after 4-5 days. If the leaks completely dry out and also begin, the source is through these lines.

Damage open the washroom waterproofing job treatment as well as re-do it very carefully. A typical and successful approach for dealing with small leakages is to treat the affected portion with concrete slurry.

Waterproofing Auckland for Dummies

Inspect the affected part of the terrace check making use of a wooden club as well as examine if it has peeled. Eliminate the loose part with a chisel as well as hammer. Re-do it thoroughly. If the leak is from the corners or from the parapet wall surface, then load all the fractures after damaging it open with cement.

Some chemicals are suggested for combining with cement, at the time of concreting. The standard method of brickbat coba is still one of the most popular of water-proofing technique in India. Waterproofing compounds are normally offered in powder and also liquid type, as they offer the dual objective of waterproofing work treatment as well as heat shielding.

Guarantee that the socketing go to this site is done before the base layer work. Make sure that there is no leak from the bathroom W.C. slab once the socketing is done. Make sure that the catches and launch pipelines are repaired properly before the brickbat coba layer. Make sure that all the brickbats are well-soaked in water, before use.

Ensure that the water-proofing compound is mixed in the mortar, for every phase of job. The overcoat needs to be lugged out in one stroke, without any kind of joints.